Powerful UV Disinfection Technology

Find out why Crossfire Technology is trusted worldwide for water disinfection.

Conventional UV Systems Face These Top 10 Issues—Crossfire Solves Them

-

1. Not effective for low UVT water

Conventional systems have limited performance for water with low UV transmittance (UVT) caused by minerals, organics, and other solids and chemicals.

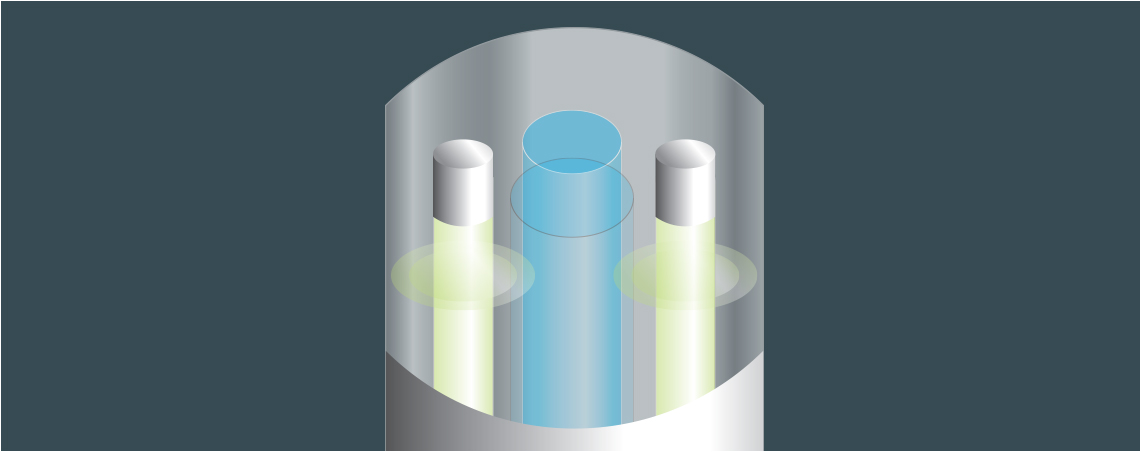

Crossfire Technology delivers a sterilizing dose of UV radiation from 360 degrees to overcome shadowing and reliably disinfect water with UVT as low as 35%, versus minimum 75% UVT for conventional systems.

-

2. Quartz fouling reduces effectiveness

Minerals and biofilm can build up on the quartz tube, reducing the disinfection dose and causing alarms.

Crossfire Technology incorporates an automatic self-cleaning mechanism that prevents the quartz from fouling without requiring harsh chemical cleaning like other conventional systems.

-

3. 'Dumb' sensors and alarm diagnostics

Most conventional systems have a single sensor that looks at the UV lamp through layers of quartz and water. The sensor does not know whether an alarm was triggered by fouled quartz, poor water quality, lamp temperature, or drop in lamp intensity. It is up to the operator to use trial and error to find the problem.

Crossfire Technology incorporates dual smart sensors for more powerful diagnostics.

-

4. Frequent maintenance and false alarms

With conventional UV systems, quartz fouling can lead to frequent nuisance alarms. The only way to avoid this is with regular maintenance to clean the quartz tube using acid.

Crossfire Technology has an automatic wiper mechanism that continuously cleans the quartz, and dual sensors for smarter alarming.

-

5. Overheating and alarms in low flow conditions

Conventional systems rely on flowing water to prevent heat build-up from UV lamps. In no flow and low flow situations, the lamps can overheat, lose output, and trigger alarms.

Crossfire Technology uses continuous forced-air cooling of lamps in the UV reactor chamber to prevent overheating.

-

6. Live transfer of pathogens from UV shadowing

Solids and quartz fouling in conventional systems can create shadows, or blind spots, in the water column where UV radiation cannot penetrate, allowing pathogens to survive.

Crossfire Technology overcomes this serious problem with its patented dual-lamp elliptical reflector design.

-

7. Down-time during maintenance

When an alarm trips in a conventional system, the operator must decommission the entire system to identify the problem by trial and error, and to carry out the necessary repairs or maintenance.

Crossfire Technology is designed with advanced diagnostics and troubleshooting features to minimize down-time and keep the system operating.

-

8. Exposure to contaminated water

In conventional systems, the UV reactor chamber must typically be drained and decommissioned to perform regular maintenance of lamps inside the quartz tubes, exposing the operator to untreated water.

Crossfire Technology has an easy-open chamber design and air-mounted lamps that maintain a safe separation between the operator and wetted parts during lamp changes and most maintenance.

-

9. Poor cold-temperature performance

Very cold water causes lamps in conventional systems to over-cool, resulting in a drop in UV output and triggering alarms.

Crossfire Technology uses air-mounted lamps with optional heating to keep the system operating effectively for air and water temperatures as low as 1°C (34°F).

-

10. Breaking the quartz during lamp replacement

Changing lamps in a conventional UV system is difficult since it requires a lot of space around the unit to remove the lamp from the quartz tube, and the fragile quartz can break adding more system down-time.

Crossfire Technology has an easy-open chamber design with air-mounted lamps for fast lamp changes with no risk of breaking the quartz.