Over 18,000 UV Pure systems are operating worldwide – with many providing years or even decades of reliable disinfection performance in potable, wastewater, and reuse applications. Over time, requirements for some sites can change, leading operators to evaluate different disinfection options to cope with higher flow requirements, changing water quality, emerging pathogenic threats or other factors.

The introduction of UV Pure’s new Hallett product line addresses these upgrade challenges with new technology, higher-capacity flow rates, and lower power consumption while continuing to provide the low-maintenance, highly reliable performance that operators trust from UV Pure.

As the UV Pure team prepares to ship the first of these new Hallett systems in early 2019, we share some answers below to common questions about the new units.

How are the new Hallett units similar to UV Pure’s proven Hallett 15xs and Hallett 30 systems?

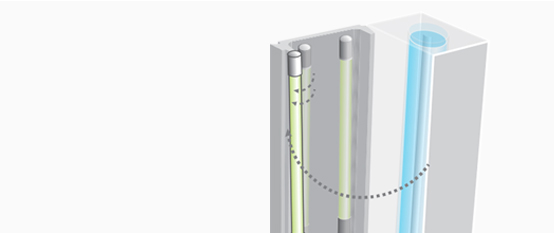

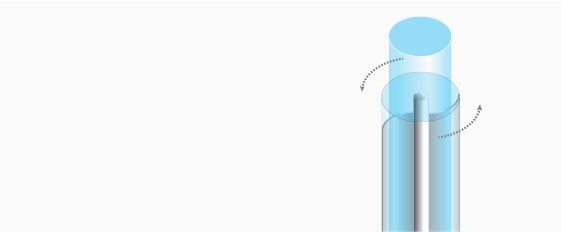

The new Hallett units are still powered by UV Pure’s patented Crossfire Technology™, which includes automatic self-cleaning wipers, smart sensors, and built-in purging to prevent fouling of the quartz sleeve by mineral scaling and biofilm. This makes Hallett systems up to 10 times more effective in difficult water applications than conventional UV systems.

How are the new Hallett systems different from existing Hallett units?

The new Hallett units have been completely redesigned with better features and operability. The new systems can handle flow rates of up to 100 gpm (378 L/min) per unit while continuing to provide robust, reliable disinfection under the toughest conditions. For higher flow applications, multiple Hallett units are connected to achieve flow up to 1 MGD (3,785 m3/day).

What happened to UV Pure’s Upstream products?

Upstream systems will be discontinued in early 2019, but UV Pure will continue to offer replacement parts and full product support for years to come. New Hallett NC systems will replace Upstream models for disinfection applications that do not require product certification or validation.

How does UV Pure ensure its systems provide the appropriate level of public health and environmental protection?

UV Pure is offering a new Hallett system that is validated to the US Environmental Protection Agency’s (EPA) UV Disinfection Guidance Manual (UVDGM) protocols, as well as to the National Water Reuse Institute’s (NWRI) UV Disinfection Guidelines for Drinking Water and Water Reuse.

What type of warranty is available for replacement lamps?

UV Pure continues to offer a 12-month limited warranty for LPHO lamps, while amalgam lamps in the new Hallett 1000 model will be covered for 16 months.

Learn More:

Click here or below to download a brochure that answers your questions about the new Hallett, or please contact us here.